At Pelican Coast Electric, we understand the critical role electrical panel labeling plays in keeping homes and businesses safe and compliant. Whether it’s a residential electrical panel labeling standard or an industrial electrical panel labeling standard, the objective is the same: to ensure safety, clarity, and compliance with regulatory codes. Without proper labeling, electricians and maintenance teams may face confusion and increased risks when working on your electrical systems.

This guide explores electrical panel labeling requirements to help you maintain a safe and efficient environment, protect property, and meet compliance standards.

Understanding Electrical Panel Labeling Standards

What are labeling standards and why do they matter?

Electrical panel labeling standards are regulatory guidelines that dictate how electrical systems should be marked to improve safety and functionality. These standards are crucial for both residential and industrial properties. They ensure that electricians can identify circuits and electrical components quickly, reducing risks during repairs, inspections, and emergency situations.

Pelican Coast Electric is committed to helping our clients adhere to these standards, safeguarding both residential and commercial environments.

Regulatory Authorities Defining Electrical Panel Labeling Standards

Codes and organizations behind labeling standards

Several governing authorities regulate electrical panel labeling requirements to protect people from electrical hazards and prevent equipment damage. The most relevant standards include:

- National Electrical Code (NEC): Article 110.22 mandates that circuit breakers and disconnects must be labeled to indicate their purpose. This standard applies to both residential and industrial systems.

- OSHA (Occupational Safety and Health Administration): OSHA enforces safety regulations, ensuring that electrical systems in workplaces are clearly labeled to minimize risks of accidents.

- Local Building Codes: Municipal authorities may have additional rules that complement NEC and OSHA standards.

Adhering to these regulations is essential for both safety and legal compliance. At Pelican Coast Electric, we stay updated on all code changes to provide accurate labeling solutions for our clients.

Electrical Panel Labeling Code and Requirements

What details should be included on labels?

To comply with electrical panel labeling codes, labels should provide essential information, including:

- Circuit identification: Every circuit must clearly state what it controls, such as “Living Room Lights” or “HVAC System.”

- Voltage and amperage ratings: Labels should indicate circuit voltage (e.g., 120V, 240V) and current capacity to avoid overloading.

- Hazard warnings: High-voltage circuits require warning labels to alert personnel to potential dangers.

- Emergency shut-off instructions: In industrial settings, panels may require instructions to quickly power down equipment during emergencies.

Well-organized labeling helps electricians perform tasks efficiently and minimizes downtime. Pelican Coast Electric can design custom labeling systems tailored to your needs.

Residential vs. Industrial Electrical Panel Labeling Standards

Key differences between residential and industrial labeling

Although the same fundamental principles apply to both residential and industrial electrical systems, there are important distinctions between the two types of labeling standards:

- Residential Electrical Panel Labeling Standards:

- Focused on clear identification of household circuits (e.g., outlets, appliances, lighting).

- Simpler panel layouts, typically requiring fewer labels.

- Labels often include references to rooms or household zones.

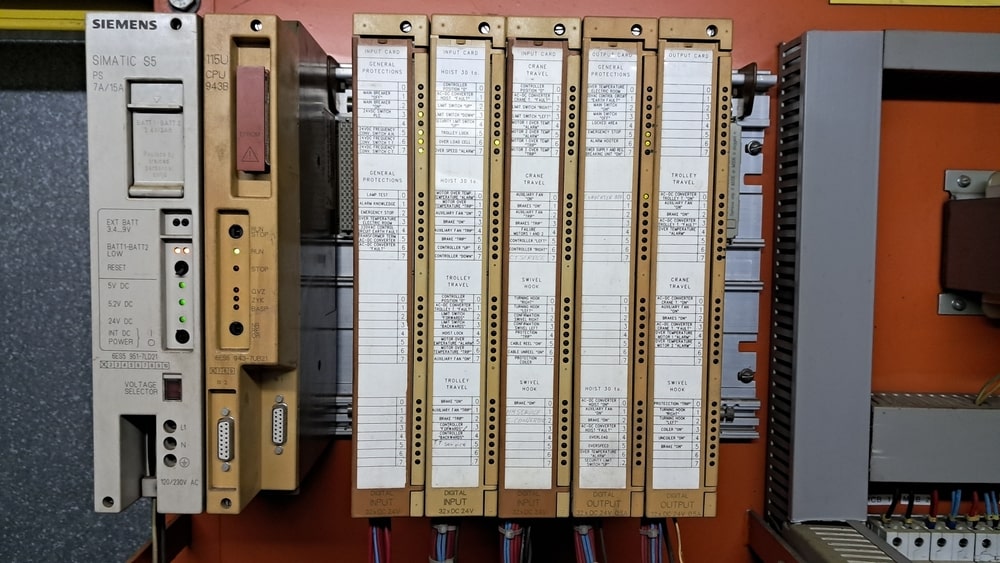

- Industrial Electrical Panel Labeling Standards:

- Designed for large, complex systems that power multiple machines or operations.

- Requires detailed labeling of control panels, circuit breakers, and disconnect switches.

- Emphasizes safety, emergency protocols, and regulatory compliance for heavy machinery.

Whether your project involves a home or a large facility, Pelican Coast Electric ensures that your labeling meets all relevant standards.

The Importance of Electrical Panel Labeling Standards

Why proper labeling is essential

Proper labeling is not just about organization—it can save lives and protect property. Key benefits of following electrical panel labeling requirements include:

- Enhanced safety: Correct labeling reduces the risk of electrical shock and fire hazards by ensuring circuits are easily identified.

- Compliance with codes: Meeting NEC and OSHA standards prevents potential fines, liability issues, and failed inspections.

- Operational efficiency: Technicians can quickly diagnose and fix electrical issues when labels are clear and accurate.

- Emergency response: In critical situations, properly labeled panels help first responders shut off power to specific areas without delay.

At Pelican Coast Electric, we prioritize safety and compliance in every labeling project.

Best Practices for Electrical Panel Labeling

How to maintain compliance and clarity

To meet electrical panel labeling code standards, follow these best practices:

- Use high-quality, durable labels: Labels must withstand heat, moisture, and other environmental factors.

- Ensure legibility: Use clear fonts and contrasting colors for easy readability.

- Keep labels up to date: Labels should reflect all changes to wiring or circuits to prevent confusion during maintenance.

- Adopt a system: Consistency matters, especially in industrial settings with complex panels. A systematic approach to labeling prevents errors.

For assistance in creating compliant labeling systems, contact Pelican Coast Electric today.

Common Labeling Mistakes to Avoid

Errors that can compromise safety and compliance

Mistakes in labeling can have serious consequences, including safety hazards and code violations. Avoid these common errors:

- Vague descriptions: Labels that say “Miscellaneous” or “General” provide no useful information.

- Outdated information: Circuit labels that are not updated after system changes can mislead technicians.

- Poor visibility: Faded, damaged, or missing labels create confusion and increase risks during emergencies.

- Failure to meet code: Skipping labeling requirements can lead to penalties or failed inspections.

With Pelican Coast Electric, you’ll avoid these pitfalls and maintain fully compliant labeling.

Pelican Coast Electric Is Your Partner for Residential Electrical Services

At Pelican Coast Electric, we are dedicated to providing top-quality residential electrical services, including compliance with residential electrical panel labeling standards. Our experienced electricians understand the unique needs of homeowners, from upgrading electrical panels to ensuring that all circuits are properly labeled for safety and convenience. We prioritize safety, efficiency, and customer satisfaction in every project. Whether you need a panel inspection, repairs, or new installations, we ensure that your home’s electrical system meets local and national electrical panel labeling codes. With Pelican Coast Electric as your trusted partner, you can rest assured that your home’s electrical system is secure, compliant, and ready to meet your family’s needs. Contact us today to schedule an appointment!

FAQ: Electrical Panel Labeling Standards

WHAT ARE ELECTRICAL PANEL LABELING REQUIREMENTS?

Electrical panel labeling requirements define what information must be displayed on circuit breakers and panels, such as circuit identification, voltage ratings, and hazard warnings.

DO RESIDENTIAL AND INDUSTRIAL PANELS FOLLOW THE SAME LABELING CODE?

While both types follow the NEC, industrial panels often require more detailed labels due to complex equipment and heightened safety risks.

HOW OFTEN SHOULD LABELS BE INSPECTED OR UPDATED?

Labels should be updated any time changes are made to the electrical system. Routine inspections ensure they remain legible and compliant with current codes.

WHAT IF MY PANEL LABELS DON’T COMPLY WITH CODE?

Non-compliant labels can result in penalties, failed inspections, and increased risks of electrical accidents. It’s best to consult a professional like Pelican Coast Electric to ensure compliance.

Conclusion

Whether for residential or industrial applications, adhering to electrical panel labeling standards is critical for safety and regulatory compliance. By implementing durable, accurate labels, you can protect both people and property from electrical hazards while ensuring efficient system management.

For expert assistance with your labeling needs, Pelican Coast Electric is here to help. Contact us today for a consultation and ensure your panels meet all required standards!